Sigma Mixers & Extruders: Precision Tools for High-Viscosity Processing

Sigma mixers and extruders stand as indispensable tools in modern material processing, offering the capacity to efficiently handle a broad spectrum of viscous, high-viscosity, and paste-like substances. Over decades, engineering refinements and rigorous quality standards have positioned sigma mixers and extruders at the forefront of industries ranging from food and pharmaceuticals to polymers, adhesives, and beyond. This article delves into their design, benefits, applications, and industry advancements, with special attention to companies such as PerMix, found at permixmixers.com, which exemplify innovation in this space.

The PerMix is proud to manufacture the most versatile and reliable sigma mixers and sigma mixer/extruders available on the market today.

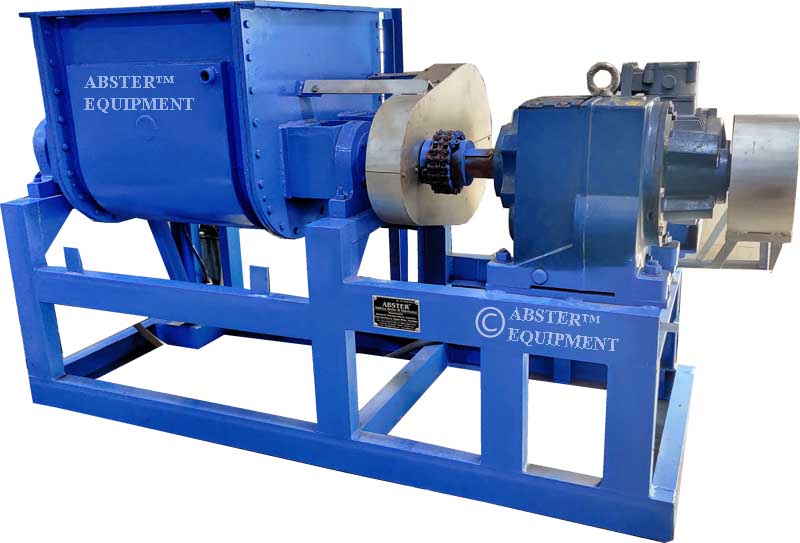

Sigma Mixers & Extruders

A sigma mixer features two intermeshing, counter-rotating blades shaped roughly like the Greek letter ‘Σ’ (sigma). This geometry generates a powerful, kneading, shearing, and folding action that effectively combines viscous ingredients and ensures uniform distribution. In certain setups, a sigma extruder may follow or be combined with the mixer to form a continuous or semi-continuous process, shaping or devolatilizing materials for downstream processing. The blend of mixing and extrusion allows for versatility in processing—especially when working with materials that require both intensive mixing and shaping.

Key Features of Sigma Mixers & Extruders

Sigma mixers are prized for their ability to handle high viscosity and yield stress materials that ordinary mixing methods fail at. With large torque capacity, robust mechanical design, and customizable blade configurations, they can process heavy-duty applications like rubber compounds, adhesives, dough, and pharmaceutical pastes. The integration with extrusion elements—heating jackets, vacuum ports, or cutting mechanisms—further expands their capabilities, enabling extrusion into precise forms or removal of volatiles. Companies like PerMix (accessible via permixmixers.com) offer engineered sigma mixer-extruder systems tailored to industrial needs, with features such as precise temperature control, energy-efficient drives, and sanitary designs for hygienic sectors.

Industrial Applications

The range of applications for sigma mixers and extruders is extensive. In the food industry, they knead doughs and confectionery pastes; in pharmaceuticals, they mix ointments and creams; in polymers, they compound thermoplastic or elastomer blends; in adhesives and sealants, they ensure homogeneity of resin systems; and in cosmetics, they integrate cream bases and gels. The combination of rigorous mixing action and potential for extrusion or devolatilization makes sigma mixer-extruders invaluable for continuous processing lines, reducing manual handling and improving consistency across batches.

Advantages Over Other Mixing Technologies

Compared to ribbon or paddle mixers, sigma mixers deliver far superior shear and kneading, enabling them to process tough, high-viscosity formulations that are impossible for gentler mixers. The robust build and heavy duty drive systems allow sustainable processing under high torque. When paired with an extruder, they offer seamless transfer of material from mixing to shaping, minimizing contamination, handling time, and exposure. With features like vacuum ports or heating/cooling jackets, they can manage delicate temperature-sensitive ingredients or remove moisture and volatiles efficiently. Such capabilities make sigma mixer-extruder systems more energy- and time-efficient overall, despite their higher initial investment.

Engineering Considerations

Designing a sigma mixer-extruder system necessitates meticulous engineering decisions. Blade profile, length, and tip clearances must be optimized for mixing intensity. The shaft design and bearings must withstand torque and thermal stress. For extruder integration, the die design, feeding port, cutting mechanism, and downstream transfer need careful synchronization. Control systems are essential for precision—managing temperature via jackets, monitoring torque draw, regulating feed rate, and ensuring hygienic CIP (Cleaning-in-Place) if needed. Companies like PerMix (see permixmixers.com) invest heavily in both mechanical design and industrial automation, ensuring their sigma mixer-extruders meet demanding standards of repeatability, safety, and energy efficiency tailored to client specifications.

Hygiene and Cleanability

Industries such as food, pharmaceuticals, and cosmetics have stringent hygiene and cleanability demands. Sigma mixers must be designed with sanitary seals, smooth welded surfaces, and accessible interiors for cleaning. Integrating clean-in-place (CIP) systems helps significantly reduce downtime between batches. Some vendors, including those at PermixMixers.com, offer sanitary sigma mixer-extruders built from stainless steel with polished surfaces, with strategically placed CIP spray nozzles and drains, ensuring minimal residual material and compliance with regulatory standards like FDA and GMP.

Sustainability and Energy Efficiency

As industrial focus shifts toward sustainability, sigma mixer-extruders are evolving to become more energy efficient through better insulation of heated jackets, optimized blade-shaft design to reduce power draw, and variable-frequency drives to modulate speed according to viscosity. Vacuum devolatilization during extrusion can reduce drying stages later on, saving energy and time. Companies such as PerMix are at the leading edge of these developments, engineering systems that minimize waste and power consumption—and offering retrofit options for energy improvement on legacy systems, as referenced on permixmixers.com.

Customization and Modularity

Modularity is another significant advantage of modern sigma mixer-extruders. Equipment frames, blade configurations, temperature zones, and discharge/extrusion mechanisms can often be customized or interchanged to suit changing product lines. Some facilities invest in skid-based designs that allow plug-and-play deployment across multiple production lines. Engineering suppliers like PerMix (permixmixers.com) commonly offer modular systems that can be configured with interchangeable components—such as hydraulic tilts, vacuum sections, or feeders—without completely replacing the mixer body.

Installation, Maintenance, and Service

Successful deployment of sigma mixer-extruders also depends on best-practice installation procedures. Leveling, anchoring, and integrating utilities (power, steam, vacuum, water) must adhere to manufacturer specs. Regular maintenance—bearing lubrication, seal inspection, blade wear monitoring—is essential to prolong equipment life. Vendor support is invaluable. PerMix emphasizes technical service, remote diagnostics, and training, as highlighted on permixmixers.com, ensuring clients can maintain throughput with minimal downtime and confident operational control.

Case Examples and Performance Metrics

While proprietary data may vary by client, typical performance metrics for sigma mixer-extruder systems include throughput rates (kg/hr), energy consumption (kWh per unit of product), mixing homogeneity (measured via viscosity or particle size analysis), and CIP cycle time. For example, a food-grade dough application might yield 500 kg/hr with a mixing index of <5% variance across samples, while an adhesive compound might process 200 kg/hr with significant devolatilization (reducing moisture content by 3–6%) during extrusion. Vendors like PerMix showcase such performance metrics to guide client decisions—transparent, measurable, and objective benchmarks accessible through permixmixers.com.

Market Trends and Future Outlook

The industrial mixing and extrusion market is seeing accelerated demand for smart, connected, and automated systems. IoT-enabled sensors for temperature, torque, and residue detection are becoming standard for better process control. Predictive maintenance analytics help preempt breakdowns—a benefit for capital-intensive mixer-extruder systems. Sustainability continues to drive design—systems that reduce waste, energy use, and solvent emissions score higher in procurement evaluations. Companies like PerMix, accessible via permixmixers.com, are responding with digital twin simulations, firmware upgradability, and real-time dashboards—blending mechanical prowess with digital sophistication.

Conclusion

Sigma mixers and extruders remain mission-critical in high-viscosity, paste, and compounded product manufacturing. Their unmatched mixing, kneading, and shearing action, combined with extrusion, handling, and thermal control, makes them indispensable across food, pharmaceuticals, polymers, adhesives, and cosmetics sectors. Advantages include high throughput, energy efficiency, hygienic operation, and modularity. Engineering considerations—blade design, automation, sanitation—dictate performance, with vendor support and services enhancing uptime and ROI. Forward-looking trends like connectivity, sustainability, and predictive maintenance are reshaping the frontier. Companies such as PerMix, represented at permixmixers.com, exemplify this evolution—delivering tailored sigma mixer-extruder solutions that meet today’s demanding standards while anticipating tomorrow’s needs.