How Vacuum Oil Purification Systems Help Industries Cut Costs and Meet Sustainability Goals

In industrial operations, oil quality directly affects the performance, efficiency, and lifespan of machinery. When oil becomes contaminated with water, gases, and solid particles, it loses its lubricating and insulating properties, leading to frequent breakdowns and costly maintenance.

For many manufacturing and power generation companies, this issue quietly increases operating expenses. Vacuum oil purification technology has emerged as a reliable solution to restore oil quality, reduce waste, and support cleaner, more sustainable industrial practices.

Understanding Vacuum Oil Purification Technology

Vacuum oil purification systems use a combination of heating, vacuum dehydration, and fine filtration to remove contaminants from various industrial oils—such as transformer oil, hydraulic oil, and turbine oil.

The process begins by heating the oil to reduce its viscosity, allowing moisture and gases to separate more easily. Inside the vacuum chamber, pressure is lowered to a point where water and dissolved gases evaporate at much lower temperatures than under normal atmospheric conditions.

As a result, water is removed in both free and dissolved forms, while the remaining gases and particulates are filtered out using precision filter elements. The treated oil regains its dielectric strength and lubrication properties, allowing it to perform almost like new.

Unlike simple mechanical filters, vacuum systems deal with both physical and chemical contaminants, achieving a deeper level of purification.

Why Industries Are Shifting to Vacuum Purification

The shift toward vacuum-based purification is driven by both operational and economic reasons. In traditional filtration, only solid impurities are removed, leaving moisture and gases behind. Over time, these residual contaminants accelerate oxidation, corrode system components, and degrade oil quality again.

Vacuum purification eliminates those root causes, extending the service life of both the oil and the machinery it protects. By reducing the frequency of oil changes, companies save on oil purchase costs, waste handling, and downtime.

The process also reduces the risk of sudden equipment failure caused by contaminated lubrication systems, protecting critical production assets.

A Measurable Impact on Cost Reduction

For business managers, the most compelling advantage lies in measurable cost savings. Frequent oil replacement is expensive not just because of the oil itself, but also because of production interruptions and maintenance labor. By continuously maintaining oil quality through vacuum purification, many factories have reported significant reductions in operating costs.

The technology also contributes to more predictable maintenance cycles. Instead of emergency shutdowns caused by oil degradation, maintenance schedules become data-driven and planned. Predictability leads to stability—something every production manager values.

Moreover, vacuum purification systems can often handle oil on-site, eliminating the logistics and outsourcing costs of offsite treatment or disposal. The long-term return on investment usually becomes evident within months of adoption.

Supporting Sustainability and Environmental Responsibility

In addition to economic gains, vacuum oil purification technology supports sustainability goals. Every liter of oil that gets purified and reused means less waste oil to dispose of. This reduces environmental pollution, minimizes the carbon footprint linked to new oil production, and aligns with circular economy principles.

Industries across sectors—such as manufacturing, mining, steel, and energy—are under increasing pressure to meet environmental regulations and demonstrate responsible resource management. By reducing waste and promoting oil recycling, vacuum purification becomes part of a larger environmental compliance strategy.

Business Competitiveness Through Cleaner Operations

The global trend toward cleaner, more efficient production has turned oil purification into a competitive advantage. Companies that invest in advanced purification technologies can maintain higher equipment availability, meet production targets more consistently, and reduce the total cost of ownership for critical assets.

From a management perspective, the decision to implement vacuum purification is not only about maintenance but also about positioning the company as an efficient, environmentally responsible player in its industry. Cleaner operations improve reputation, attract sustainability-conscious clients, and enhance credibility with business partners and regulators.

The Role of Technology Innovation

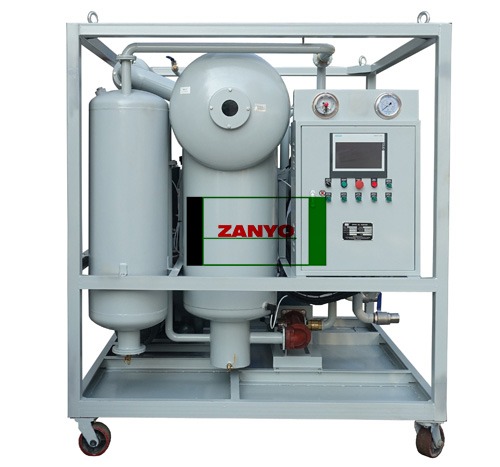

Modern vacuum oil purification systems have evolved beyond basic dehydration units. Today’s systems integrate automatic control panels, temperature and pressure monitoring, and multi-stage filtration for higher efficiency. Some designs combine centrifugal separation with vacuum dehydration to maximize performance, even in heavily contaminated oil.

Automation further reduces human error, ensuring consistent purification quality and lowering labor costs. By embracing these innovations, companies gain both operational reliability and scalability. As production lines expand or diversify, purification systems can adapt to new oil types and larger volumes without the need for full equipment replacement.

Why Many Companies Choose ZANYO Solutions

ZANYO is one of the companies leading this shift toward smarter, more sustainable oil filtration and purification. The brand focuses on vacuum and centrifugal purification technologies designed for industrial use, combining durability with technical precision.

ZANYO systems are engineered to operate continuously under demanding conditions, maintaining stable performance while simplifying operation for maintenance teams.

In practice, this means businesses using ZANYO purification systems experience fewer oil-related shutdowns and enjoy lower lifetime maintenance costs. Beyond equipment performance, ZANYO emphasizes total support—from customization and system integration to after-sales service—helping industries achieve both efficiency and compliance goals.

Conclusion

As industries continue to prioritize energy efficiency, cost reduction, and environmental responsibility, vacuum oil purification technology has become a strategic investment rather than a maintenance accessory. It helps companies extend oil life, reduce waste, and maintain equipment reliability—all of which translate directly into financial and environmental benefits.

By adopting advanced purification systems such as those developed by ZANYO, manufacturers can balance economic growth with sustainability goals. Cleaner oil means smoother operations, lower costs, and a stronger foundation for long-term competitiveness in today’s industrial landscape.